Stay Updated With New Products + Industry Insights

FREE "Better Water Book: A Holistic Guide to pH Management, Soil Health, and Sustainable Agriculture"

Complete guide to pH management, soil biology, and sustainable agriculture with case studies, technical information, and proven strategies - instant download when you subscribe!

By subscribing, you agree to receive marketing emails from CTC Waterworks. You can unsubscribe at any time.

BIG—Vacuum Cleaning Technology

Manual (MVC) and Automatic (AVC) vacuum filters for granular/heavy solids.

Decades of Proven Performance

The MVC/AVC vacuum cleaning system represents decades of field-proven technology. Our vacuum scanner design has been refined over generations of agricultural use, delivering reliable performance in the harshest environments.

From early manual systems to today's automated controllers, the core vacuum technology remains a testament to robust engineering and practical design.

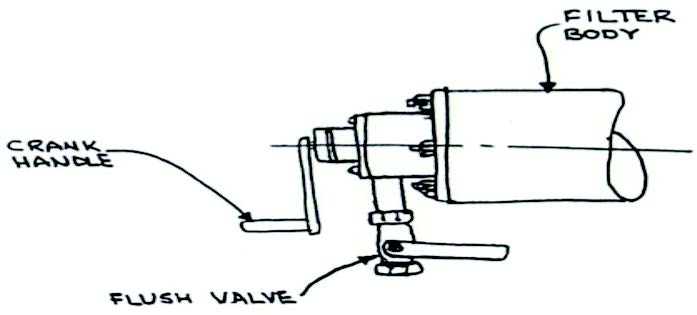

Vacuum Scanner Action

Internal vacuum scanner arm with indexed nozzles sweeps the screen interior during cleaning cycles. Powerful suction created by differential pressure extracts debris through rapid backflush. The scanner systematically covers the entire screen surface for thorough cleaning.

- Vacuum nozzles sweep screen interior

- High suction extracts heavy debris

- 10-20 second cleaning cycles

Control Options

Manual (MVC):

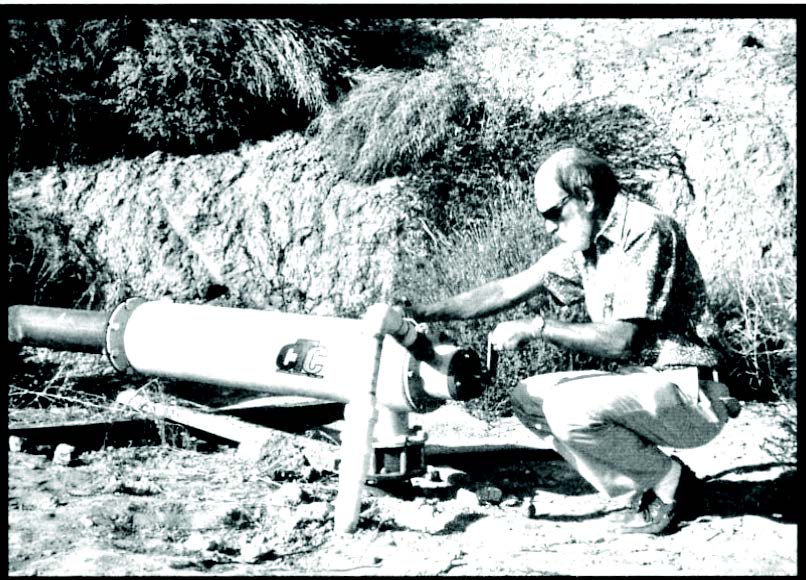

Operator initiates cleaning cycle via hand crank or manual valve. Scanner sweeps screen and purges debris. Simple mechanical operation—ideal for accessible sites with predictable cleaning schedules.

Automatic (AVC):

Differential pressure (ΔP) sensor or timer automatically triggers motor-driven cleaning cycles. Set ΔP threshold (5-15 PSI) or time interval for completely hands-free operation at remote sites.

Best For: Wells, rivers, and canals with sand, silt, clay, and heavy granular solids. Vacuum technology excels with high debris loading, fine mesh screens (80-120 mesh), and applications requiring minimal water loss during cleaning cycles.

Manual Vacuum Cleaning (MVC)

MVC (Manual Vacuum Cleaning) systems use operator-initiated cleaning cycles. Turn the hand crank or open the manual valve to activate the vacuum scanner—it sweeps the screen interior and purges debris through rapid backflush. Ideal for accessible sites where periodic manual maintenance fits operational workflow.

Operator Control

Manual initiation—clean when you need it

Rapid Cycles

10-20 second cleaning, minimal downtime

Low Water Loss

Efficient purge—only debris backflushed

MVC & AVC Model Matrix

| Size | Manual Model (MVC) | Auto Model (AVC) | Screen Part # | Flow (gpm) | Screen Length | Mesh | Perf | Notes |

|---|---|---|---|---|---|---|---|---|

| 4" | BA611 | BA594 | A4052 | 500 | 24" | 80 | .032 | Small systems |

| 6" | BA610 | BA602 | A4080 | 800 | 36" | 60 | .032 | Mid-size |

| 8" | BA609 | BA604 | B4103 | 1000 | 48" | 60 | .032 | Common model |

| 10S | BA608 | BA605 | B4033S | 1500 | 60" | 60 | .032 | High load |

| 10M | BA597 | BA680 | B5032 | 2000 | 90" | 60 | .032 | Heavy-duty |

| 10L | BA596 | BA675 | B5025 | 3200 | 120" | 60 | .032 | Jumbo |

Note: All MVC models include complete filter assembly with head, body, manual vacuum scanner mechanism, purge valve, and one standard screen. Custom sizes and configurations available—contact engineering for details.

BIG Series Vacuum Cleaning Specifications

Common specifications for both manual (MVC) and automatic (AVC) vacuum cleaning systems. Dimensions and flow rates are identical—only the control mechanism differs.

| Model | Size (nominal) | Connection | Flow Range (gpm) | Screen Length (in) | Standard Mesh/Perf | Approx. Weight (lb) |

|---|---|---|---|---|---|---|

| MVC/AVC-2 | 2" | 2" NPT | 20-80 | 18 | 20-120 mesh | 50 |

| MVC/AVC-3 | 3" | 3" NPT | 50-150 | 24 | 20-120 mesh | 85 |

| MVC/AVC-4 | 4" | 4" NPT | 100-300 | 30 | 20-120 mesh | 135 |

| MVC/AVC-6 | 6" | 6" Flange | 300-700 | 36 | 20-120 mesh | 275 |

| MVC/AVC-8 | 8" | 8" Flange | 500-1200 | 42 | 20-120 mesh | 425 |

Important: Flow ranges are guidelines for typical installations. Actual capacity depends on screen mesh size, solids loading, and acceptable head loss. Vacuum systems handle higher debris loads than brush systems. Contact engineering for application-specific sizing. Custom sizes beyond 8" available.

Replacement Parts & Service Components

| Size | Body | Head | Inlet | O-ring | Blue Wedge | Gasket | Notes |

|---|---|---|---|---|---|---|---|

| 3NPT | B4475 | A4472 | B578 | A575 | A174 | — | — |

| 4NPT | B4527 | A4526 | B612 | A618 | A619 | — | — |

| 6 | B4529 | B4528 | B623 | A620 | A622 | — | — |

| 8 | B4572 | B4573 | B1060 | A3779 | A1073 | — | — |

Parts Availability: All replacement parts are stocked by authorized dealers. Vacuum nozzles and scanner arms are field-serviceable. For part numbers, availability, and pricing, contact your local dealer or CTC Waterworks engineering.

Mesh & Perforation Quick Guide

Vacuum cleaning excels across a wide mesh range—from coarse to fine. Particularly effective with 80-120 mesh for demanding drip irrigation applications.

| Application | Recommended Mesh | Micron Range | Notes |

|---|---|---|---|

| Drip Irrigation (Heavy Solids) | 100-120 mesh | 125-149 µm | Vacuum excels with fine mesh + high debris |

| Drip Irrigation (Moderate Solids) | 80-100 mesh | 149-177 µm | Standard drip emitter protection |

| Micro-Sprinkler | 50-80 mesh | 177-297 µm | Medium mesh for granular debris |

| Intake Protection | 20-40 mesh or 1/16" perf | 420-840 µm | Coarse pre-filtration for pump protection |

Vacuum Advantage: Vacuum cleaning handles fine mesh (100-120) with high solids loading better than brush technology. The powerful suction extracts heavy granular debris that would quickly plug fine screens. Ideal when you need maximum filtration combined with heavy debris capacity.

Compare Other Technologies

Brush Cleaning

Compare brush cleaning technology (BIF/RAB) for fibrous organic matter and moderate solids loads. Rotating brushes mechanically scrub screens clean.

Self-Cleaning Overview

Detailed comparison of automatic vacuum (AVC) vs automatic brush (RAB) technologies to help you choose the right solution for your application.

Frequently Asked Questions

Explore All Cleaning Options

Vacuum technology (MVC) is available in Semi-Automatic and Fully Automatic configurations for BIG, BIG-S, and GNG series filters.

TIG filters do not support Brush/Vacuum/RAB cleaning options.

Ready to Select Your Vacuum Cleaning System?

Our engineering team will help you choose between manual and automatic vacuum cleaning based on your water quality, solids loading, and site accessibility.