Welcome to CTC Waterworks

Our new website is taking off

We're actively expanding our digital platform with new products, technical resources, and engineering tools. As we build, some pages may be incomplete or under development.

Currently Adding:

- Product specifications and technical data sheets

- Installation guides and engineering resources

- Sizing calculators and application tools

Need information now?

Our engineering team is available to assist with specifications, pricing, and technical support.

Call (509) 901-7476

Stay Updated With New Products + Industry Insights

FREE "Better Water Book: A Holistic Guide to pH Management, Soil Health, and Sustainable Agriculture"

Complete guide to pH management, soil biology, and sustainable agriculture with case studies, technical information, and proven strategies - instant download when you subscribe!

By subscribing, you agree to receive marketing emails from CTC Waterworks. You can unsubscribe at any time.

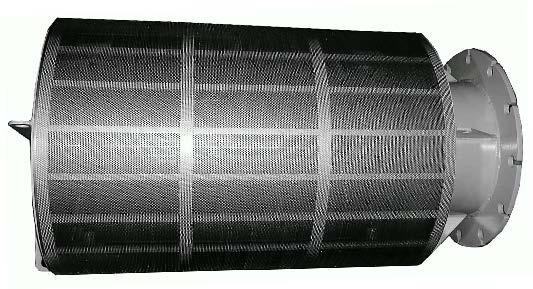

Standard Suction Screens

Robust intake protection for surface and submerged pumping.

About Standard Suction Screens

Standard Suction Screens are robust intake filters for surface or submerged pumping applications. They prevent debris from entering the pump while offering a simple, maintenance-friendly design with no moving parts. Ideal for low-flow or manual-service systems where automatic cleaning is not required.

Why Choose Standard Suction Screens?

No Moving Parts

Simple fixed design with no actuators, motors, or controls. Reliable intake protection with minimal maintenance requirements and long service life.

Easy Maintenance

Lift screen from water, hose off debris, reinstall. Typical service time 15-30 minutes. Replaceable screen elements for extended service life.

Robust Construction

Durable steel construction with replaceable screen elements. Available in epoxy-coated mild steel or stainless steel for corrosive environments.

Versatile Applications

Compatible with pump intakes, canal sumps, and pond applications. Surface or submerged mounting. Optional stands for sediment control.

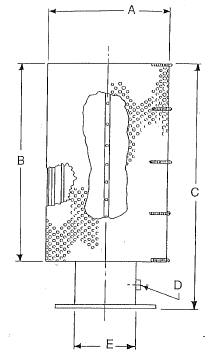

Standard Suction Screen Specifications

Select model based on pump flow rate and connection type. All dimensions in inches.

| Flow (GPM) | A (in) | B (in) | C (in) | E (in) |

|---|---|---|---|---|

| 100 | 14 | 13 | 17 | 3 NPTM |

| 200 | 14 | 15 | 19 | 4 NPTM |

| 300 | 14 | 17 | 21 | 5 FLG |

| 400 | 16 | 17 | 24 | 6 FLG |

| 600 | 16 | 23 | 31 | 8 FLG |

| 800 | 16 | 28 | 33 | 10 FLG |

| 1000 | 24 | 20 | 28 | 10 FLG |

| 1200 | 24 | 22 | 30 | 10 FLG |

| 1400 | 24 | 25 | 33 | 12 FLG |

| 1600 | 24 | 28 | 36 | 12 FLG |

| 2000 | 24 | 34 | 42 | 14 FLG |

| 2400 | 24 | 40 | 48 | 16 FLG |

| 3000 | 30 | 40 | 48 | 18 FLG |

| 3600 | 36 | 40 | 48 | 20 FLG |

| 4000 | 36 | 45 | 59 | 20 FLG |

| 4500 | 36 | 54 | 64 | 22 FLG |

| 5000 | 36 | 59 | 69 | 24 FLG |

| 5500 | 36 | 64 | 75 | 24 FLG |

| 6000 | 36 | 69 | 81 | 24 FLG |

| 6500 | 36 | 74 | 86 | 30 FLG |

| 7000 | 36 | 79 | 91 | 30 FLG |

| 7500 | 36 | 84 | 97 | 30 FLG |

| 8000 | 36 | 89 | 102 | 30 FLG |

| 8500 | 36 | 94 | 108 | 36 FLG |

Materials: Available in mild steel with epoxy coating or 304/316 stainless steel options. All dimensions in inches. NPT = National Pipe Thread (threaded connection), FLG = Flanged connection. Screen elements: stainless steel perforated plate or woven mesh. Contact our filtration specialists for material selection guidance based on water chemistry and application requirements.

Key Features

- Durable steel construction with replaceable screen elements

Robust design for long service life. Screen elements can be replaced without replacing entire assembly—reduces long-term costs.

- Fixed manual design (no power or actuation required)

Simple, reliable operation with no electrical or mechanical controls. No power consumption or automation complexity.

- Coarse-screen intake protection for irrigation and industrial pumps

Prevents large debris (leaves, twigs, algae) from entering pump. Protects pump impellers and extends pump service life.

- Compatible with pump intakes, canal sumps, and pond applications

Versatile mounting options: direct pump connection, surface mounting, or submerged installation with optional stands.

- Optional deflection cones or stands for sediment control

Accessories available to redirect sediment flow and elevate screen above pond/canal bottom. Contact our filtration specialists for recommendations.

Installation Note: Standard Suction Screens install directly on pump suction line or can be mounted on optional stands for canal/pond applications. Ensure adequate submersion depth for screen length plus 6-12 inches clearance. Screen should not contact bottom to avoid sediment accumulation. For specific installation guidance, contact CTC filtration specialists with your site conditions and pump configuration.

Fish-Compliant Intake Protection

Standard Suction Screens are fish-compliant when properly sized and configured. The fixed screen design with appropriate perforation sizes (typically 3/32" or smaller) and adequate screen surface area maintains low approach velocities that meet regulatory requirements for fish protection.

Our filtration specialists can calculate approach velocities and provide documentation for permit applications to ensure your screen meets local, state, and federal fish protection standards including WDFW, NOAA Fisheries (NMFS), and other regulatory agencies.

Compliance Note: Proper sizing is critical for fish compliance. Larger screen surface area reduces approach velocity. Contact our filtration specialists with your flow requirements and local regulatory standards for compliant screen sizing.

Mesh & Perforation Reference

| Mesh | Open Area (%) | Equivalent Perf | Typical Use |

|---|---|---|---|

| 30 | 50 | 0.020–0.025 | Intake |

| 60 | 31 | 0.015–0.020 | Micro |

| 80 | 31 | 0.010–0.012 | Drip |

| 120 | 31 | 0.008–0.010 | Fine Emitter Protection |

Compare Suction Screen Options

Self-Cleaning Suction Screens (SCS2)

For automated cleaning and high-debris environments, consider SCS2 Self-Cleaning Suction Screens. Spray bar system cleans screen without lifting from water.

Passive Fish Screens (PSF)

For fish-compliant water intakes meeting NOAA/NMFS standards, view PSF Passive Fish Screens. Wedge-wire construction with passive fish protection.

Frequently Asked Questions

Ready to Protect Your Pump with Standard Suction Screens?

Our filtration specialist team will help you select the right model, recommend optimal screen configuration, and design a complete intake protection system for your pumping application.