Welcome to CTC Waterworks

Our new website is taking off

We're actively expanding our digital platform with new products, technical resources, and engineering tools. As we build, some pages may be incomplete or under development.

Currently Adding:

- Product specifications and technical data sheets

- Installation guides and engineering resources

- Sizing calculators and application tools

Need information now?

Our engineering team is available to assist with specifications, pricing, and technical support.

Call (509) 901-7476

Stay Updated With New Products + Industry Insights

FREE "Better Water Book: A Holistic Guide to pH Management, Soil Health, and Sustainable Agriculture"

Complete guide to pH management, soil biology, and sustainable agriculture with case studies, technical information, and proven strategies - instant download when you subscribe!

By subscribing, you agree to receive marketing emails from CTC Waterworks. You can unsubscribe at any time.

Water Box Product Images

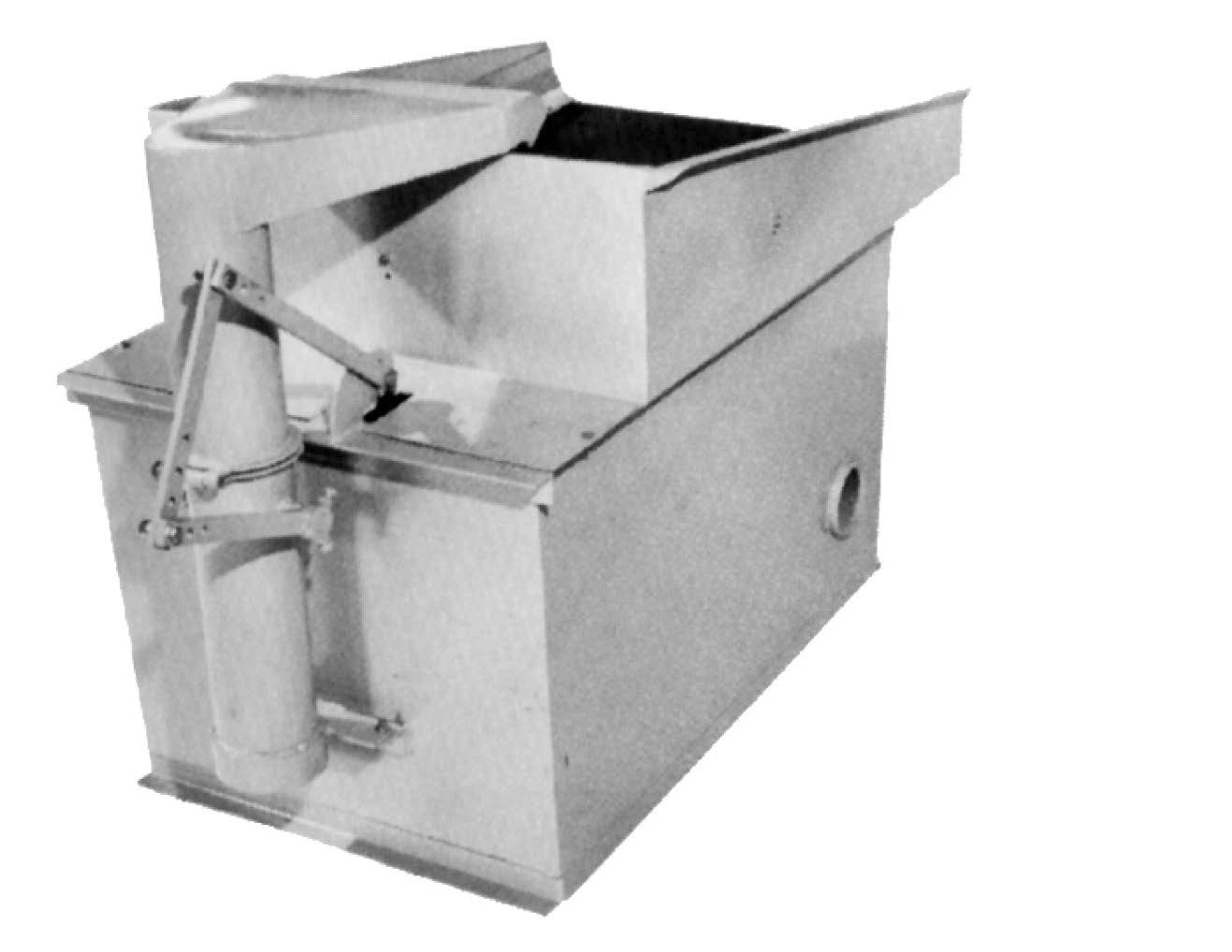

Water Box Filter (Primary)

General-purpose intake screening with large screen area and float valve control.

Water Box Installation

Typical field installation showing float valve assembly and piping connections.

Custom Configuration

Custom Water Box with specialized port arrangements for unique installations.

Water Box (WB) Intake Filters

General-purpose intake screening for ponds, canals, and sumps.

About Water Box Systems

The Water Box is a general-purpose intake screen system for ponds, canals, and sumps. It features a large screen area and float-valved level control to deliver consistent flow to pumps and pressure filters. Commonly installed upstream of BIG or TIG filters for coarse screening.

Why Choose Water Box?

Large Screen Area

High surface area maintains low intake velocity, preventing screen blinding and extending time between cleanings. Handles heavy debris loading effectively.

Float Valve Control

Self-regulating float valve assembly maintains consistent water level and flow. No external controls or power required—simple, reliable operation.

Overflow Protection

Built-in overflow ports prevent chamber overfilling during high-water conditions or float valve malfunction. Safe, fail-tolerant design.

System Integration

Works seamlessly with BIG or TIG pressure filters downstream. Water Box handles coarse screening, pressure filter provides fine filtration.

Water Box Specifications

Select Water Box model based on pump flow requirements. All dimensions in inches.

| Flow (GPM) | Screen Area (in²) | H | L | W | Valve | Suction |

|---|---|---|---|---|---|---|

| 200 | 748 | 20 | 24 | 26 | 4" | 3" |

| 300 | 1288 | 27 | 30 | 48 | 6" | 3" |

| 400 | 1656 | 27 | 38 | 48 | 8" | 4" |

| 500 | 2088 | 27 | 38 | 60 | 10" | 4" |

| 600 | 2520 | 27 | 38 | 72 | 10" | 5" |

| 700 | 2784 | 27 | 50 | 60 | 10" | 6" |

| 800 | 3360 | 27 | 50 | 72 | 10" | 6" |

| 1000 | 4200 | 27 | 50 | 84 | 12" | 6" |

| 1200 | 5040 | 27 | 60 | 96 | 12" | 6" |

| 2000 | 6540 | 27 | 60 | 109 | 12" | 6" |

| 2400 | 10080 | 36 | 120 | 84 | (2) 12" | (2) 8" |

| 3000 | 11520 | 46 | 120 | 96 | (2) 12" | (2) 8" |

Materials: Available in mild steel with epoxy coating or 304/316 stainless steel options. All dimensions in inches. H = Height, L = Length, W = Width. Float valve assembly, overflow ports, and large screen surface included with all models. Contact engineering for site-specific sizing and material selection guidance.

Key Features

Float Valve Assembly

Self-regulating float valve maintains consistent water level inside the chamber. As pump draws water out, the valve opens to allow more in, ensuring continuous flow without air entrainment. No external controls or power required.

- Self-regulating level control

- No power or controls needed

- Prevents air entrainment

Overflow Ports

Built-in overflow ports provide fail-safe protection during high-water conditions or float valve malfunction. Water safely exits chamber before overfilling occurs. Simple, reliable safety feature.

- High-water protection

- Float valve backup

- Fail-tolerant design

System Design: Water Box filters are typically installed at the water source (pond, canal, sump) with suction line running to pump. The large screen area and low intake velocity prevent debris accumulation and extend cleaning intervals. Pair with BIG or TIG pressure filters downstream for complete coarse-to-fine filtration protection.

Mesh & Perforation Reference

| Mesh | Open Area (%) | Equivalent Perf | Typical Use |

|---|---|---|---|

| 30 | 50 | 0.020–0.025 | Intake |

| 60 | 31 | 0.015–0.020 | Micro |

| 80 | 31 | 0.010–0.012 | Drip |

| 120 | 31 | 0.008–0.010 | Fine protection |

Complete Your Filtration System

Pair with BIG Series

Add downstream BIG inline filters for pressure filtration. Water Box handles coarse screening, BIG provides fine polishing with automatic cleaning.

Pair with TIG Series

Compact true-inline TIG filters for space-constrained installations. Works downstream of Water Box for secondary polishing.

Frequently Asked Questions

Ready to Protect Your System with Water Box?

Our filtration specialist team will help you select the right Water Box model, configure valve and suction sizes, and design a complete intake-to-pressure filtration system for your application.