Stay Updated With New Products + Industry Insights

FREE "Better Water Book: A Holistic Guide to pH Management, Soil Health, and Sustainable Agriculture"

Complete guide to pH management, soil biology, and sustainable agriculture with case studies, technical information, and proven strategies - instant download when you subscribe!

By subscribing, you agree to receive marketing emails from CTC Waterworks. You can unsubscribe at any time.

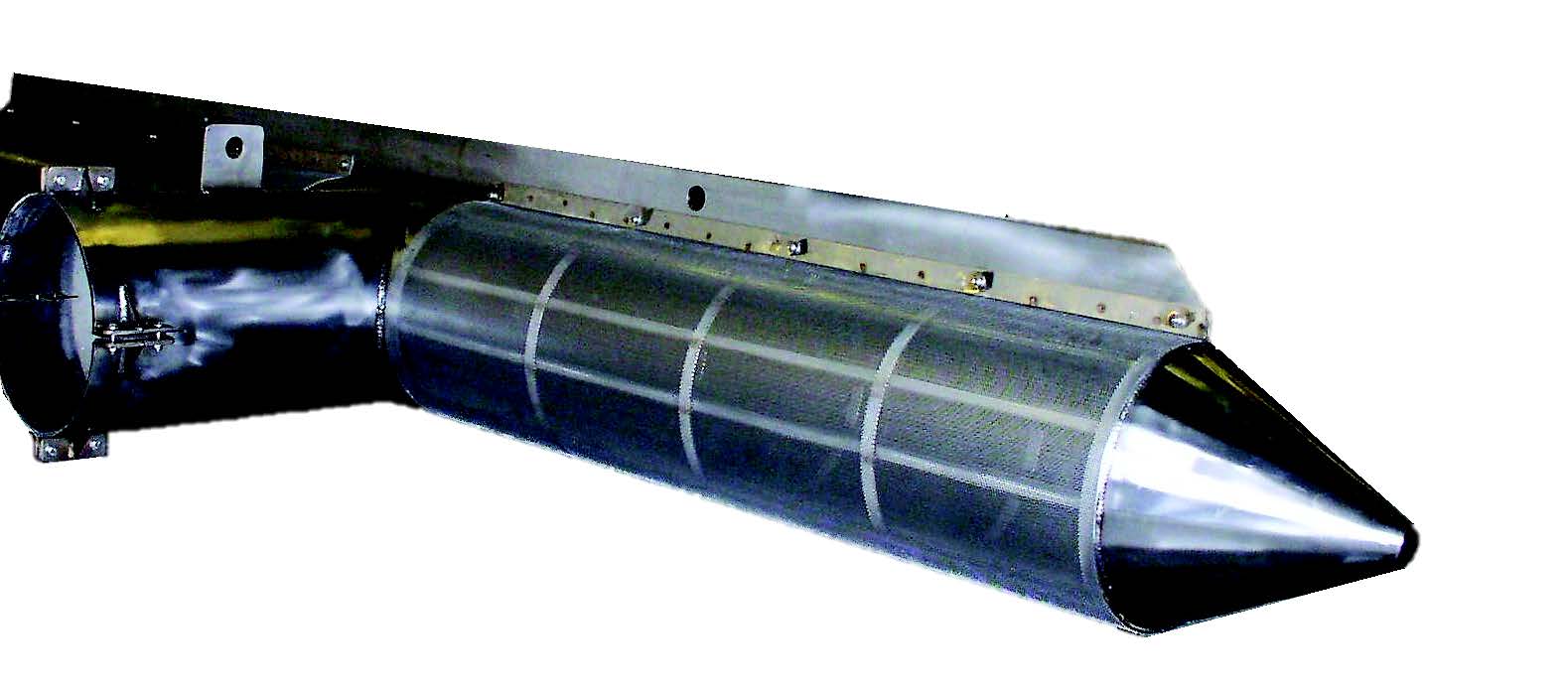

SCS2 Self-Cleaning Suction Screens

Available with configurations meeting NOAA/WDFW fish-screen approach-velocity and open-area criteria — approved for surface-water and dam intake use.

SCS2 = Self-Cleaning Suction 2nd Generation

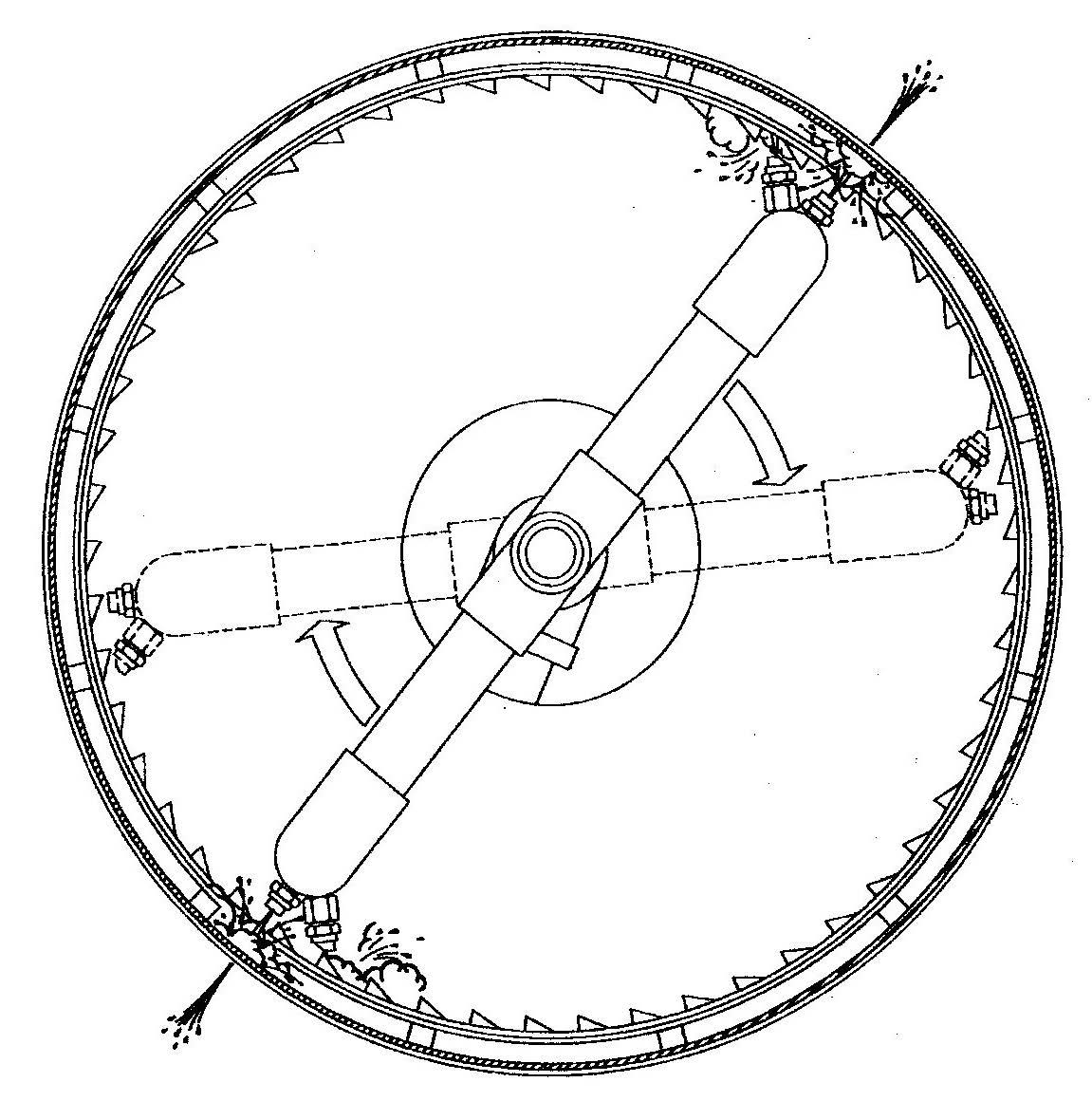

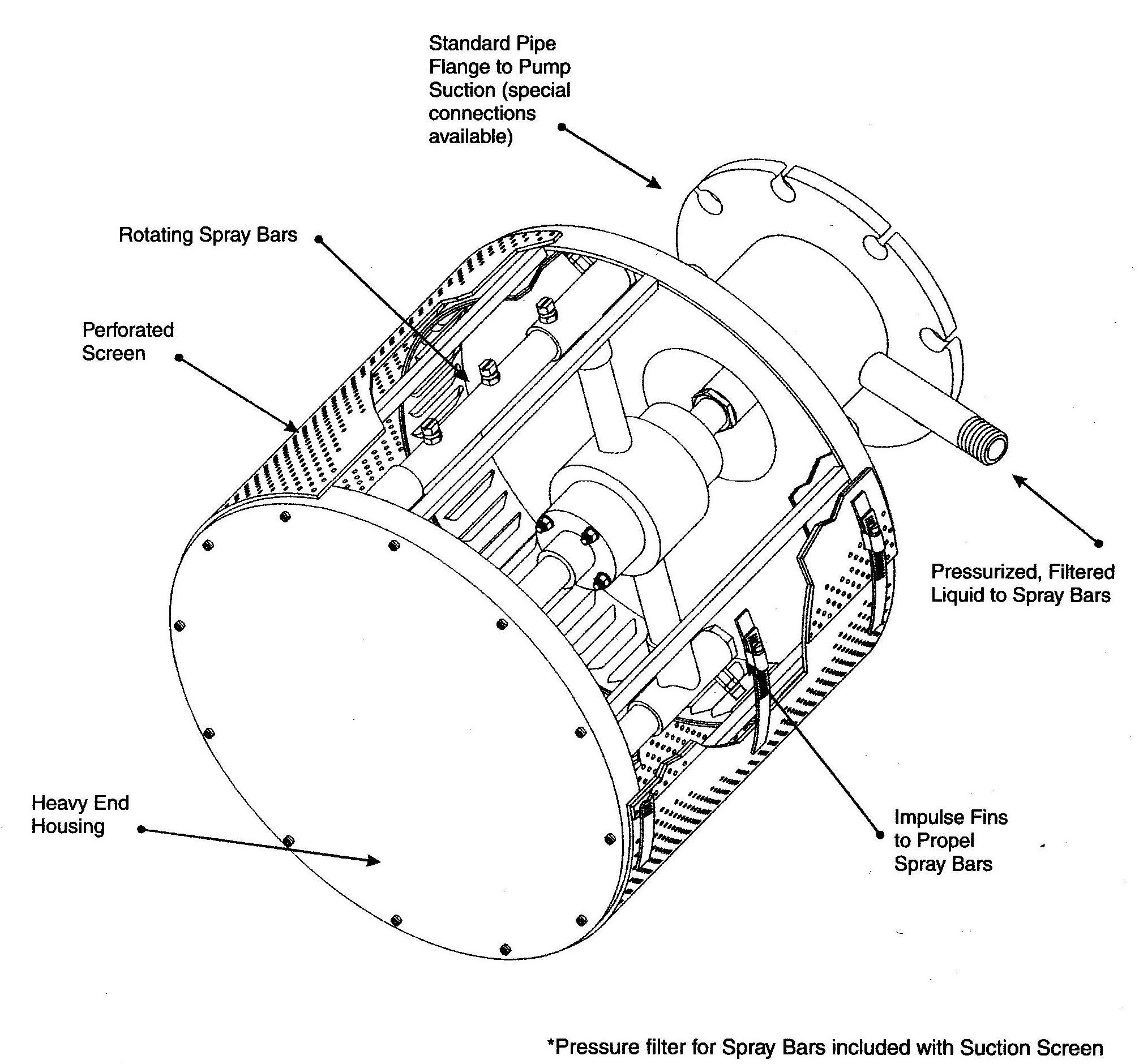

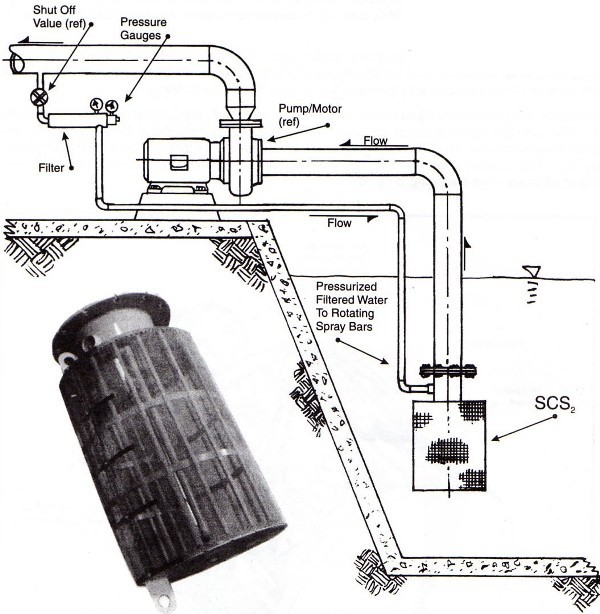

The SCS2 features a stationary perforated cylinder with an automated rotating internal spray bar. Water from the pump discharge side is diverted to the spray bar, which rotates inside the screen to eject accumulated debris while maintaining continuous intake flow. The screen does not rotate—there are no external moving parts. Ideal for agricultural, municipal, and industrial intakes in rivers, canals, ponds, sumps, and manure lagoons with organic debris, algae, and moderate to high solids loading. Configurations available meeting NOAA/WDFW fish-screen criteria for hydropower and dam applications.

Why Choose SCS2?

Continuous Protection

Automated cleaning maintains intake flow without shutdowns. Internal spray bar rotation prevents blinding—no manual intervention required during operation.

Spray-Bar Cleaning

High-pressure spray bar rotates inside stationary screen to eject debris. Simple, proven technology with minimal maintenance requirements and no external moving parts.

Rugged Options

Harsh-environment sealed bearings, deflection cones for debris shedding, multiple mounting configurations for various installations.

System Integration

Pair with BIG or TIG inline filters for complete two-stage protection. SCS2 handles bulk debris, inline filter provides final polishing.

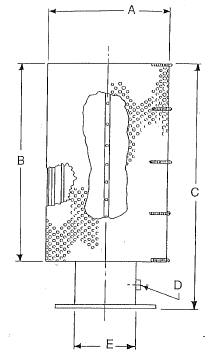

Self-Cleaning Suction Screens — Specifications

Select SCS2 model based on your pump flow rate. Spray bar requirements are minimal—typically 0.5-2% of intake flow.

| Flow (GPM) | Item # | Matching Pressure Filter | A (in) | B (in) | C (in) | D | E | Spray Bar GPM | Est. Weight (lb) |

|---|---|---|---|---|---|---|---|---|---|

| 100 | BA217 | BA509 | 14 | 13 | 17 | ¾ NPTM | 3 NPTM | 11 | 60 |

| 200 | BA218 | BA509 | 14 | 15 | 19 | ¾ NPTM | 4 NPTM | 12 | 65 |

| 300 | BA219 | BA509 | 14 | 17 | 21 | ¾ NPTM | 5 FLG | 15 | 70 |

| 400 | BA220 | BA509 | 16 | 17 | 24 | 1 NPTM | 6 FLG | 17 | 76 |

| 600 | CA221 | AA559 | 16 | 23 | 31 | 1 NPTM | 8 FLG | 26 | 82 |

| 800 | CA222 | AA559 | 16 | 28 | 33 | 1 NPTM | 10 FLG | 34 | 90 |

| 1000 | CA223 | AA559 | 24 | 20 | 28 | 2 NPTF | 10 FLG | 26 | 140 |

| 1200 | CA224 | AA559 | 24 | 22 | 30 | 2 NPTF | 10 FLG | 29 | 160 |

| 1400 | DA225 | AA559 | 24 | 25 | 33 | 2 NPTF | 12 FLG | 31 | 180 |

| 1600 | DA226 | AA559 | 24 | 28 | 36 | 2 NPTF | 12 FLG | 34 | 210 |

| 2000 | DA227 | AA560 | 24 | 34 | 42 | 2 NPTF | 14 FLG | 41 | 230 |

| 2400 | DA228 | CA63 | 24 | 40 | 48 | 2 NPTF | 16 FLG | 46 | 260 |

| 3000 | DA229 | CA63 | 30 | 40 | 48 | 2 NPTF | 18 FLG | 46 | 300 |

| 3600 | DA260 | CA63 | 36 | 40 | 48 | 2 NPTF | 20 FLG | 46 | 433 |

| 4000 | BA563 | CA64 | 36 | 45 | 59 | 2 NPTF | 20 FLG | 56 | 465 |

| 4500 | BA564 | CA64 | 36 | 54 | 64 | 2 NPTF | 22 FLG | 59 | 500 |

| 5000 | BA565 | CA64 | 36 | 59 | 69 | 2 NPTF | 24 FLG | 64 | 535 |

| 5500 | BA566 | CA64 | 36 | 64 | 75 | 2 NPTF | 24 FLG | 69 | 570 |

| 6000 | BA567 | CA64 | 36 | 69 | 81 | 2 NPTF | 24 FLG | 74 | 605 |

| 6500 | BA571 | CA64 | 36 | 74 | 86 | 2 NPTF | 30 FLG | 87 | 640 |

| 7000 | BA572 | CA64 | 36 | 79 | 91 | 2 NPTF | 30 FLG | 100 | 675 |

| 7500 | BA573 | CA64 | 36 | 84 | 97 | 2 NPTF | 30 FLG | 115 | 710 |

| 8000 | BA574 | CA64 | 36 | 89 | 102 | 2 NPTF | 30 FLG | 130 | 745 |

| 8500 | BA575 | CA64 | 36 | 94 | 108 | 2 NPTF | 36 FLG | 145 | 780 |

Note: Pressure Filter .032 perf. SCS2 no smaller than .062 perf on outside (.093 standard).

How SCS2 Self-Cleaning Works

Stationary Screen Cylinder

Perforated stainless steel cylinder remains stationary—the screen does not rotate. Water flows inward through screen openings while debris accumulates on exterior. The internal spray bar rotates to clean the screen surface continuously, with no external moving parts.

- Stationary screen—no external moving parts

- 3/32" or 1/8" perforations (fish-friendly)

- No flow interruption during cleaning

- Proven in manure ponds / dairy lagoons

Spray-Bar Action

High-pressure spray bar positioned inside the stationary cylinder rotates and directs water outward through screen openings. As the spray bar rotates past each section of screen, accumulated debris is ejected. Spray activates on timer or differential pressure.

- 40-60 PSI spray pressure recommended

- 5-20 GPM depending on screen size

- Timer or ΔP controlled activation

Fish-Compliant Intake Protection

SCS2 screens meet most fish protection requirements when properly sized. The sweeping flow across the stationary screen cylinder prevents fish impingement—fish are swept away rather than pinned. Approach velocity through screen openings is calculated to stay below regulatory limits (typically 0.2-0.5 fps). Available with 3/32" or 1/8" perforations meeting fish exclusion standards. Our filtration specialists can provide compliance documentation and approach velocity calculations for permit applications.

SCS2 Applications

Proven across diverse water sources and challenging intake conditions

Surface Water Intakes

- Rivers and canals with organic debris, leaves, algae

- Agricultural ponds and sumps

- Dam penstock intakes (fish-compliant configurations)

- Hydropower facilities requiring continuous operation

High-Solids Environments

- Manure ponds and dairy lagoons — proven reliable in high-solids, fibrous slurry for effluent irrigation

- Municipal wastewater and reclaimed water systems

- Industrial process water with variable debris loads

- Aquaculture and fish farm intakes

Dairy & Livestock Operations

SCS2 screens excel in manure lagoon and dairy effluent applications where fibrous solids, high organic loads, and continuous operation are critical. The internal spray bar effectively removes sticky, fibrous materials without clogging, making it ideal for lagoon pumping systems and effluent irrigation networks. No external moving parts means reliable performance even in harsh slurry environments.

Available Options & Configurations

Deflection Cones

Conical deflectors mounted at screen ends shed large debris and prevent impingement. Recommended for applications with heavy leaf/twig loading or floating debris.

- Reduces large debris accumulation

- Improves flow distribution

- Extends cleaning intervals

Sealed Bearings

Harsh-environment sealed bearing assemblies for abrasive water, heavy debris, or continuous-duty applications. Extends service life 2-3× over standard bearings.

- Sand/silt protection

- Extended lubrication intervals

- Continuous-duty rated

Mounting Kits

Multiple mounting configurations for vertical, horizontal, or angled installations. Includes flotation collars, anchor systems, and adjustable brackets.

- Floating or fixed installation

- Canal, pond, or sump mounting

- Adjustable for water level changes

Custom Configurations: CTC filtration specialists can design custom SCS2 solutions for unique site conditions, extreme environments, or specialized applications. Contact us to discuss water quality, installation constraints, and regulatory requirements for your project.

Replacement Parts & Service Components

| Part Category | Fitment (models/sizes) | Part # | Notes |

|---|---|---|---|

| Replacement Screens | Size-specific (4", 6", 8", 10", 12") | Contact dealer | 3/32" or 1/8" perforations, 304 SS |

| Bearing Assemblies | All SCS2 models | Contact dealer | Standard or sealed bearing options |

| Seal Kits | All SCS2 models | Contact dealer | Complete seal replacement kit |

| Spray Bars | Length-specific to screen size | Contact dealer | Complete assembly with nozzles |

| Spray Nozzles | All SCS2 models | Contact dealer | Individual nozzles or complete set |

| Drive Motors | Size-specific (fractional HP) | Contact dealer | 120V or 240V, NEMA rated |

| Deflection Cones | Size-specific (4", 6", 8", 10", 12") | Contact dealer | Optional debris deflectors |

Parts Availability: All replacement parts are stocked by authorized dealers. Field service kits include bearings, seals, and hardware for annual maintenance. Screens typically have 5-10 year service life. For part numbers, availability, and pricing, contact your local dealer or CTC Waterworks engineering.

Compare Suction Screen Options

Standard Suction Screens

For manual-service applications with low-flow or clean water, consider Standard Suction Screens. Simple fixed design with no moving parts.

Passive Fish Screens (PSF)

For fish-compliant water intakes meeting NOAA/NMFS standards, consider PSF screens. No power required, passive fish protection.

Pair with BIG Series

Add downstream BIG inline filter for two-stage protection. SCS2 removes bulk debris, BIG provides fine polishing.

Frequently Asked Questions

Custom Solutions

SCS2 screens are configurable for multi-unit installations and specialized applications. Work with our engineering team to design the optimal intake protection solution for your unique requirements.

Multi-Unit Installation

Multiple SCS2 screens configured in parallel banks for high-flow applications. Independent cleaning cycles ensure continuous flow while individual units are serviced.

Custom Application

SCS2 screens adapted for specialized installations including unique mounting configurations, custom screen materials, and site-specific environmental requirements.

Ready to Protect Your Intake?

Our filtration specialist team will help you select the right SCS2 model, configure options, and design a complete two-stage filtration system for your water source and flow requirements.